Why Aton™ is the top grade of diamonds

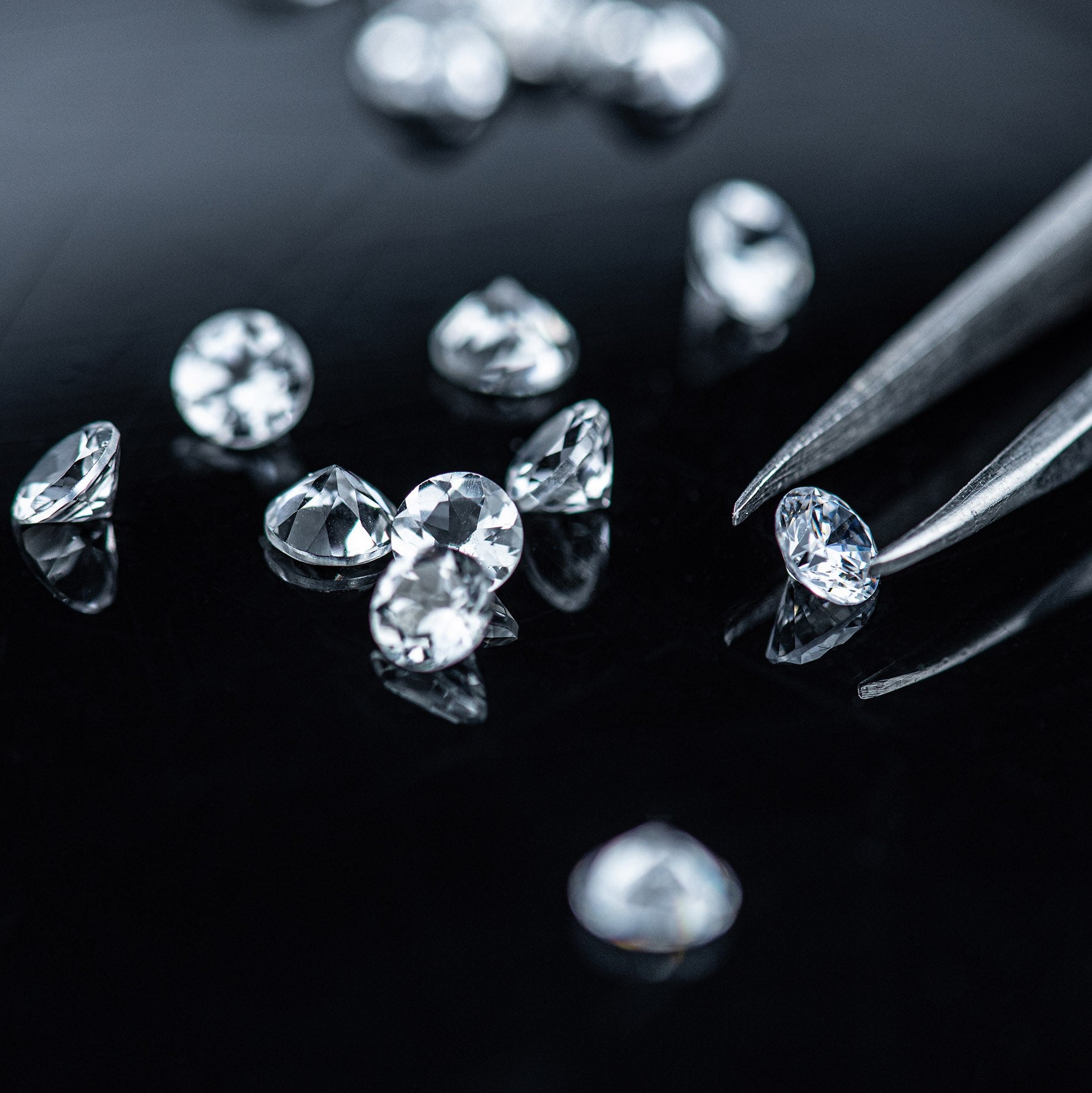

Azuro Republic Aton™ diamond cutting, in addition to GIA and Sarine Light certifications, pursues the ultimate cutting perfection and diamonds that exceed the 4Cs. We collaborate with GIA Labortory Facetware® to cut diamonds, ensuring they meet GIA Triple EX standards. Every main diamond and accent diamond is a perfect eight hearts and eight arrows, and the cutting of every angle is among the most rigorous in the world.

Only select colorless and clean diamonds

The world's largest diamond mining areas are located in Russia, Africa, Canada, Australia, and India. Different mining areas produce diamonds with varying undertones (or diamond hues) due to differences in soil and climate. This is why you might find that even diamonds with D, E, or F color grades can appear darker or grayer. Azuro Republic selects only diamonds from raw mines with no color hue, ensuring the most perfect clarity and brilliance in terms of color grade.

*Each diamond is formed at a depth of at least 150 kilometers below the Earth's surface, at a temperature between 1300 and 2000 degrees Celsius, and at a pressure of over 70 tons, in order for carbon to be converted and recrystallized.

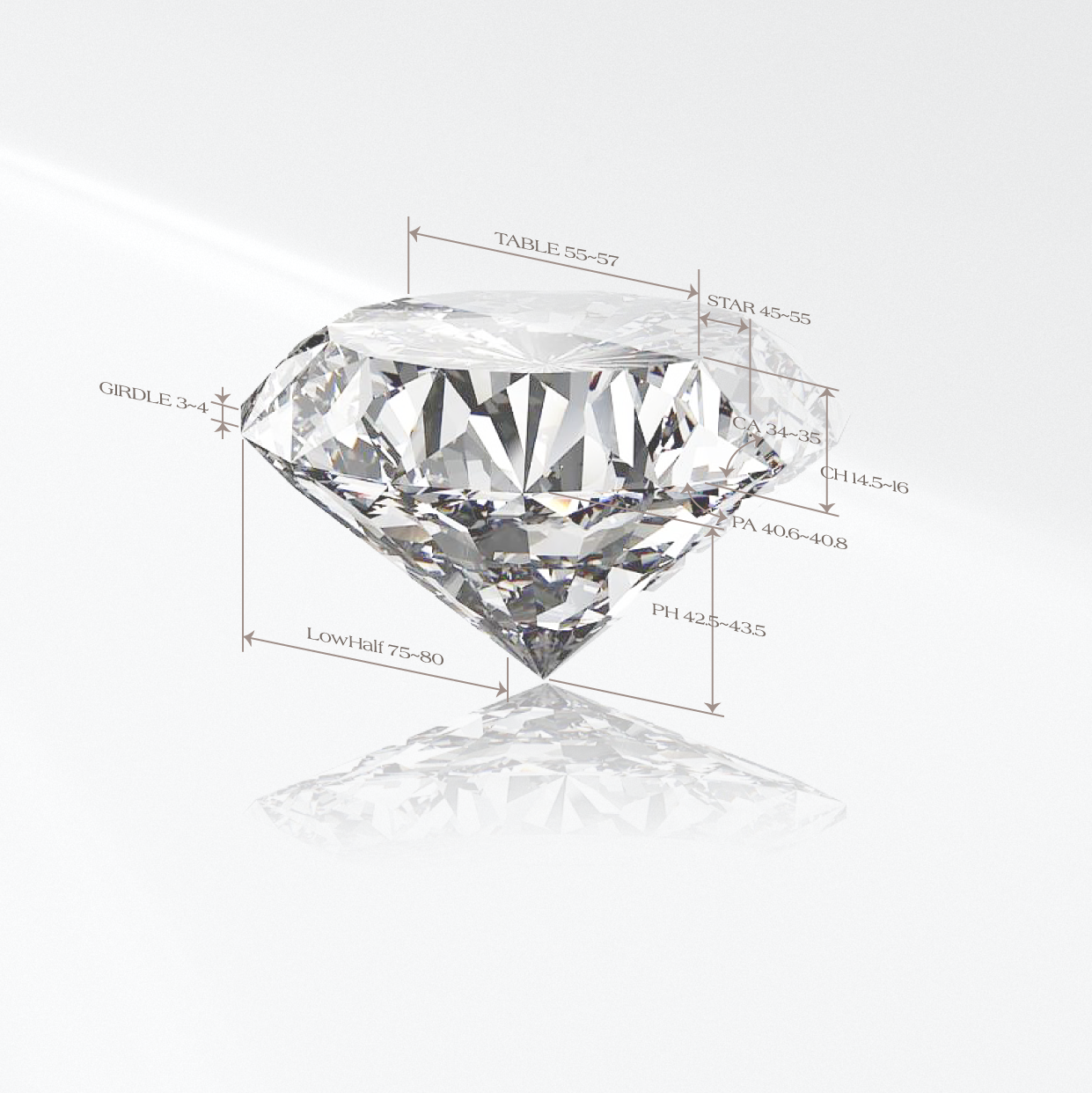

Exceptional diamond cutting

Diamond cutting surpasses the Tolkosky Ideal Cut. Diamond cutting is absolutely the most important aspect of a diamond. From the Tolkosky Ideal Cut proposed in 1919 to the GIA's perfectly proportioned Triple EX, with over 30 years of experience, Azuro Republic Aton™ offers diamonds with cuts that surpass both the Tolkosky and GIA Triple EX standards, including table, crown, pavilion, girdle, depth, and 10 other proportions.

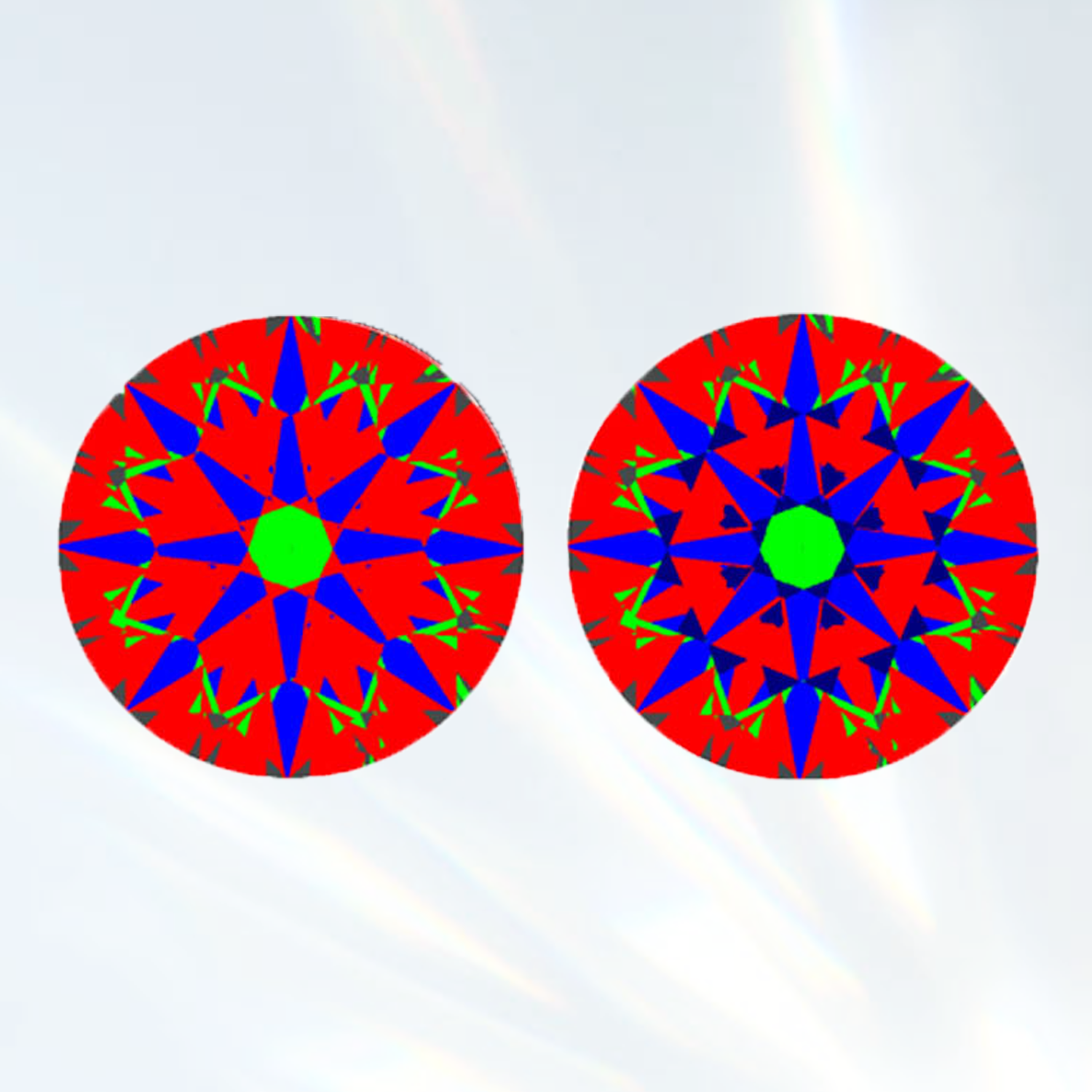

Perfect Fire Shining Light

Creating diamonds beyond the 4Cs, Azuro Republic has partnered with Israel's Sarine Technology as a global strategic partner. Top-quality diamonds, cut in Belgium, will be sent to the Sarine laboratory for fire and light symmetry certification. Sarine Light™ fills the gap in GIA certification regarding Brilliance, Sparkle, Fire, and Light Symmetry, which are not specifically graded. Only the highest-grade diamonds can meet the Sarine Light™ Ultimate 1, 2, and 3 certification standards.

Laser anti-counterfeiting labels and three types of certificates

Each diamond that is GIA certified, Sarine Light™ certified, and cut using Azuro Republic's patented Aton™ cut is one of only 1-3 diamonds out of every 100,000. We will then affix a laser anti-counterfeiting label to these rare and beautiful diamonds.

Azuro Republic Aton™ Top-Cut GIA Diamond

Our commitment to quality and pursuit of excellence

Analyzing diamonds

Azuro's GIA team first categorizes the rough diamonds by hue, undertone, and color. This is a more rigorous classification method than GIA's, first identifying colorless undertones, and then classifying them into D, E, and F colors. This classification process yields only 5 diamonds out of 6000.

Exquisite Machining

Next, Azuro Republic's teams in Belgium and Israel will analyze these top-quality raw materials, with appraisers confirming their authenticity and using laser scanning equipment to complete 3D modeling, in order to cut out the most perfect shape and carat size.

(Fire) Flash Authentication

Azuro Republic has formed a global strategic partnership with Israel's Sarine Technology. Top-quality diamonds, cut in Belgium, will be sent to the Sarine laboratory for fire and light symmetry certification. Sarine Light™ fills the gap in GIA certification regarding Brilliance, Sparkle, Fire, and Light Symmetry, which are not specifically graded there. Only the highest-grade diamonds can meet the Sarine Light™ Ultimate 1, 2, and 3 certification standards.